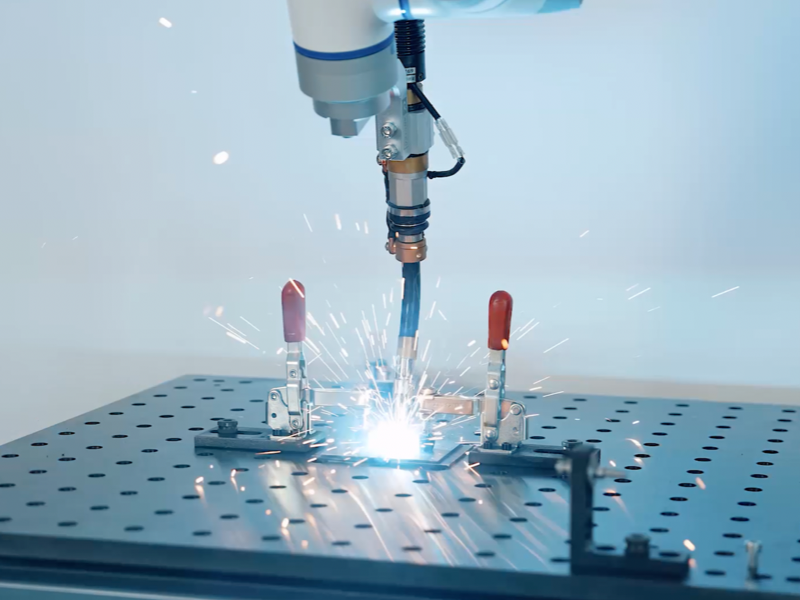

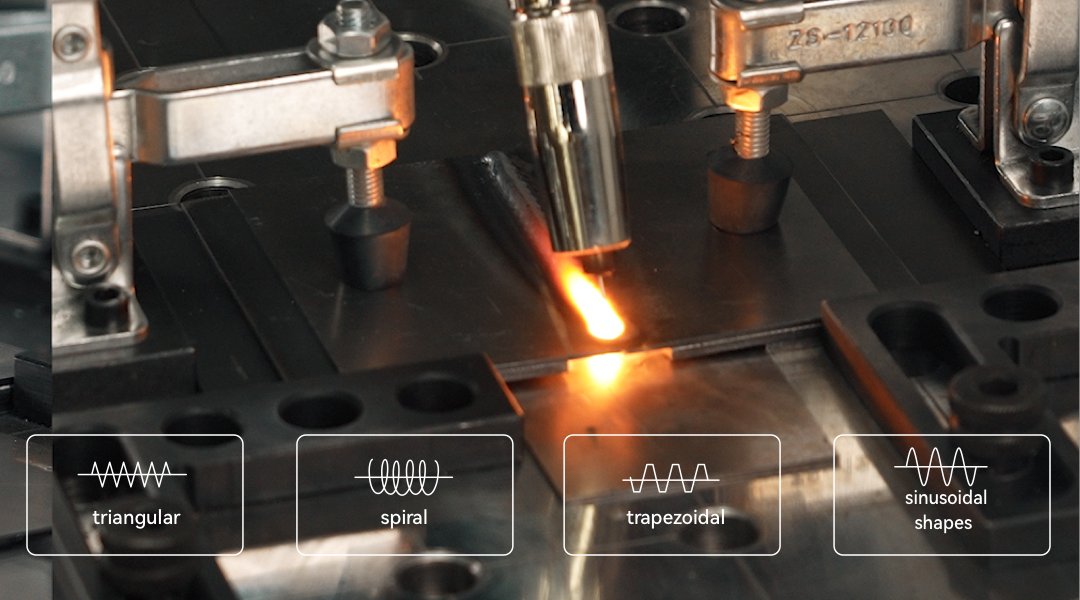

Dobot's exceptional professional welding process package facilitates the seamless integration of arc welding and laser welding applications, compatible with various mainstream welding machines and supports welding patterns, such as triangle, spiral, trapezoidal, and sine, ensuring a robust and versatile solution.

With simple steps on the process package, the robot is compatible with various welding machine, saving deployment time.

Dobot's self-developed prevision control algorithms can achieve ±0.02 mm positioning accuracy for optimum quality and efficiency.

Dobot collaborative robots feature 5-level adjustable collision sensitivity, satisifies for diverse welding scenarios' needs.

Dobot cobots can work flexibly in small areas, equipped with self-developed process packages, arc welding, laser welding solutions can be built quickly for different welding tasks for metal processing.

Dobotの専門家との連絡を確立

自動化の変革に参加しましょう。より効率的な将来を目指して、一緒に頑張りましょう。

File sent

Join Dobot+ Ecosystem to Forge Deeper Partnerships